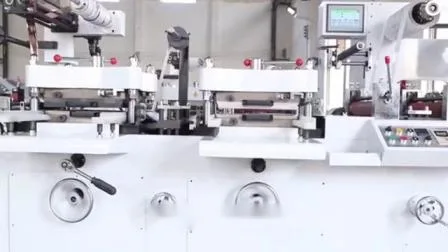

Fully Automatic Creasing and Die Cutting Machine with Auto Feeder Collection

Overview Product Description RDMG-1080 Fully automatic die cutting machine 1. Complete design, accurate installation, hi

Overview

Product Description

1. Complete design, accurate installation, high stability, high security, low noise.2. Adopt worm, worm gear, crankshaft transmission, high cutting pressure, high durability.3. High precision intermittent mechanism, high cutting precision, running steadily.4. Adopt European feeder, suction adjustable, stable, precise, good paper applicability;5. Non-stop feeding, pre-stacking and delivery mechanism can shorten the auxiliary time, improve the efficiency.6. Human-friendly designed die frame and baseplate, makes installation, adjustment convenient;7.Pneumatic die locking device, die frame fixed more steadily, accurately and time saving.8.Front lay, side lay, feeding device fine tuning device, paper positioning more accurate. 9.Double, crooked, empty optoelectronic position control, ensure the paper in the right position, reduce waste.10.Electronic control modular design, adopt imported electronic components, ensure the accuracy and reliability.11.Touch screen man-machine interface, real-time monitor the running situation, makes machine adjustment, trouble shooting more convenient. 12.Adopt imported server control system for foil stamping, feeding and collecting aluminum foil accurately.13.Adopt industrial tablet PC, touch screen input data, automatic programming, greatly saving aluminum foil.14.Cycling cooling oil supply system ensure the movement parts get adequately lubricated to ensure the durability.15.Adopt fixed quantity at fixed timing oil supply system, ensure the movement parts get adequately lubricated to let better durability. Product Parameters

What can we do for you?We have been engaged in rigid box equipment for more than 20 years, and can provide you with a full set of rigid box production solutions.What machines can we offer?For developing a rigid box production line, the following machines are related.

Die cutting machine, V grooving machine, Magnet pasting machine, Ribbon pasting machine, Case making machine, Rigid box making machine, Gluing machine, Box wrapping machine, Assembling machine, Bubble pressing machine, Packing machine, etc. We will tailor the most suitable plan and equipment for you according to your needs.Warranty?1 year from the date of installationInstallation and training?Usually, we will send a technician to the customer''s factory to help the customer install the machine and train the workers. The period is 7-15 days (depending on the model). During this period, customers will pay for round-trip air tickets, hotel accommodation, meals, and local transportation.

Due to the pandemic, we currently suspended this service until the end of the epidemic. However, we will help buyer to install the machine online via wechat or whatsapp.What''s the delivery time?10-30 days after receive the payment.How to confirm the quality of machines?After the production and debugging of the machine is completed, we provide online demonstration services, so you can fully confirm the equipment.

Basic Info.

| Model NO. | RDMG-1080 |

| Production Capacity | 10sets/Month |

Product Description

Product Description

1. Complete design, accurate installation, high stability, high security, low noise.2. Adopt worm, worm gear, crankshaft transmission, high cutting pressure, high durability.3. High precision intermittent mechanism, high cutting precision, running steadily.4. Adopt European feeder, suction adjustable, stable, precise, good paper applicability;5. Non-stop feeding, pre-stacking and delivery mechanism can shorten the auxiliary time, improve the efficiency.6. Human-friendly designed die frame and baseplate, makes installation, adjustment convenient;7.Pneumatic die locking device, die frame fixed more steadily, accurately and time saving.8.Front lay, side lay, feeding device fine tuning device, paper positioning more accurate. 9.Double, crooked, empty optoelectronic position control, ensure the paper in the right position, reduce waste.10.Electronic control modular design, adopt imported electronic components, ensure the accuracy and reliability.11.Touch screen man-machine interface, real-time monitor the running situation, makes machine adjustment, trouble shooting more convenient. 12.Adopt imported server control system for foil stamping, feeding and collecting aluminum foil accurately.13.Adopt industrial tablet PC, touch screen input data, automatic programming, greatly saving aluminum foil.14.Cycling cooling oil supply system ensure the movement parts get adequately lubricated to ensure the durability.15.Adopt fixed quantity at fixed timing oil supply system, ensure the movement parts get adequately lubricated to let better durability. Product Parameters

| Maxpaper size: | 1080x780mm |

| Min paper size: | 400x360mm |

| Max cutting size: | 1075x770mm |

| Die chase inner size: | 1100x790mm |

| Cutting plate size: | 1080x780mm |

| Min gripper margin size: | 7mm |

| Cutting precision: | ≤±0.1mm |

| Max cutting pressure: | 300T |

| Max cutting speed: | 7500S/H |

| Pre-stacking height: | 1550mm |

| Delivery pile height: | 1400mm |

| Cardboard: | 0.1~2mm |

| Corrugated paper: | <4mm |

| Main motor power: | 11KW |

| Total power: | 18KW |

| Dimension: | 4850(+1650)x2100(+1600)x2350mm |

| Weight: | 15.6T |

Die cutting machine, V grooving machine, Magnet pasting machine, Ribbon pasting machine, Case making machine, Rigid box making machine, Gluing machine, Box wrapping machine, Assembling machine, Bubble pressing machine, Packing machine, etc. We will tailor the most suitable plan and equipment for you according to your needs.Warranty?1 year from the date of installationInstallation and training?Usually, we will send a technician to the customer''s factory to help the customer install the machine and train the workers. The period is 7-15 days (depending on the model). During this period, customers will pay for round-trip air tickets, hotel accommodation, meals, and local transportation.

Due to the pandemic, we currently suspended this service until the end of the epidemic. However, we will help buyer to install the machine online via wechat or whatsapp.What''s the delivery time?10-30 days after receive the payment.How to confirm the quality of machines?After the production and debugging of the machine is completed, we provide online demonstration services, so you can fully confirm the equipment.

previous:

Semi

Send to us