Jingwei Brand Fis

Overview 24h Online Customer Service Product Description FIS-1500 Flat Clipping Machine Precision:0.1mm processing lengt

Overview

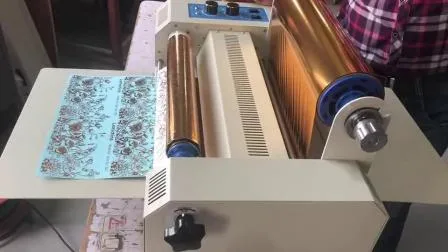

FIS-1500 Flat Clipping Machine

Precision:0.1mm

processing length:FIS-1000 700-1100mm FIS-1500 700-1520mm

flat width:33.3mm

Suitable for covering various types of carding machine flat clothing.

The combination of top pressing, side pressing, and wrapping is completed through a program, and the desired flatness after wrapping is achieved for the purpose of textile mills. Realize a negative difference of no more than 0.05mm, and complete the processing characteristics of different machine amplitudes, different cover plate keel forms and materials by adjusting the adaptability of the jaws.

Adopting two sets of high-precision guide rails for independent packaging and pressing cars and CNC running motors, ensuring smooth operation and precise positioning of packaging and pressing wheels.

Programmed top pressure and side pressure can tightly adhere the bottom of the flat to the keel plane, and under pressure

The modular movement of the pressure wheel component of the pressure car ensures that the iron sheet clamped on the edge of the flat can securely fit onto the keel.

Basic Info.

| Model NO. | JW series |

| Customized | Non-Customized |

| Condition | New |

| After-sales Service | Guide User Personnel to Learn Installation |

| Processing Length | Fis-1000 700-1100mm Fis-1500 700-1520mm |

| Input Voltage | 220V |

| Flat Width | 33.3mm |

| Movable Speed | 30-80mm/S |

| Compressed Air Pressure | 0.5-0.75MPa |

| Power | 350W |

| Precision | 0.1mm |

| Transport Package | Crates |

| Trademark | Jingwei |

| Origin | China |

| HS Code | 84481900 |

| Production Capacity | 120 Pieces/Year |

Product Description

24h Online Customer Service Product Description

FIS-1500 Flat Clipping Machine

Precision:0.1mm

processing length:FIS-1000 700-1100mm FIS-1500 700-1520mm

flat width:33.3mm

Suitable for covering various types of carding machine flat clothing.

The combination of top pressing, side pressing, and wrapping is completed through a program, and the desired flatness after wrapping is achieved for the purpose of textile mills. Realize a negative difference of no more than 0.05mm, and complete the processing characteristics of different machine amplitudes, different cover plate keel forms and materials by adjusting the adaptability of the jaws.

Adopting two sets of high-precision guide rails for independent packaging and pressing cars and CNC running motors, ensuring smooth operation and precise positioning of packaging and pressing wheels.

Programmed top pressure and side pressure can tightly adhere the bottom of the flat to the keel plane, and under pressure

The modular movement of the pressure wheel component of the pressure car ensures that the iron sheet clamped on the edge of the flat can securely fit onto the keel.

Send to us